CSR

-

Important Results and Sustainability Performance in2024

-

Words from the Management

-

Sustainable Management

-

Sustainable Governance

-

Sustainability and Innovation

-

Environmental Sustainability

-

Common Prosperity and Growth

-

Download Report

-

互動專區

-

影音專區

Supply Chain Management

Suppliers are among our most important partners. To build a sustainable and resilient supply chain, we incorporate suppliers’ ESG performance into our selection and management processes. We have established a responsible and transparent supply chain management framework that requires suppliers to provide a safe working environment, prohibit forced labor and child labor, respect and protect employee rights, prevent environmental degradation, and uphold ethical business practices. Through annual audits and capacity-building measures, we ensure our suppliers’ compliance with Acter’s Code of Conduct. By guiding our supply chain toward sustainable transformation, we not only mitigate potential risks but also make a meaningful contribution to the United Nations Sustainable Development Goals (SDGs).

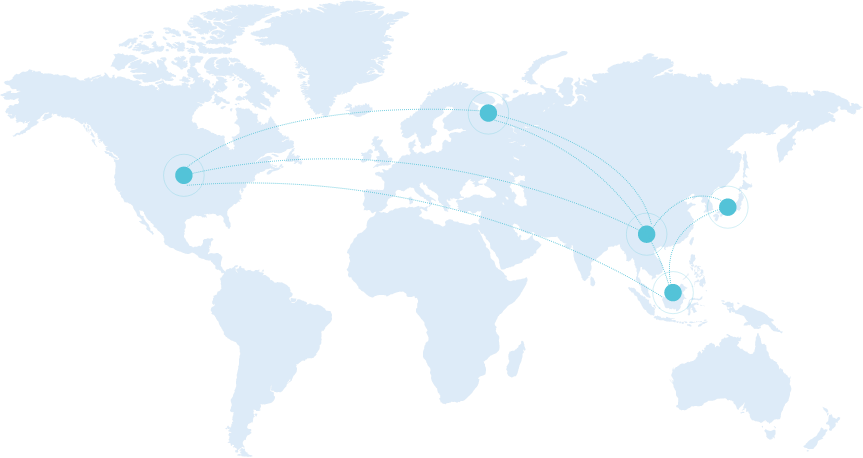

Supply Chain Structure

We categorize our suppliers as contractors and materials and equipment suppliers based on their attributes. Suppliers whose annual transaction amount exceeds NT$10 million are designated as "key suppliers". As of 2024, Acter has accumulated 6,428 partners worldwide, encompassing regions such as Taiwan, Europe, the United States, Northeast Asia, Southeast Asia, and China. We prioritize a balanced approach between local procurement and supply chain diversity to minimize carbon emissions across the supply chain, create local employment opportunities, and mitigate overall supply chain risks.

Statistics on the geological distribution of suppliers over the years

| 2022 | 2023 | 2024 | ||||

|---|---|---|---|---|---|---|

| Q’ty (No. of suppliers) | Ratio | Q’ty (No. of suppliers) | Ratio | Q’ty (No. of suppliers) | Ratio | |

| Taiwan | 5,817 | 99.13% | 6,076 | 99.14% | 6,375 | 99.18% |

| China | 20 | 0.34% | 20 | 0.33% | 20 | 0.31% |

| North East Asia | 3 | 0.05% | 3 | 0.05% | 3 | 0.05% |

| South East Asia | 1 | 0.02% | 2 | 0.02% | 2 | 0.03% |

| Europe and the United States | 27 | 0.46% | 28 | 0.46% | 28 | 0.44% |

| Total | 5,868 | 100% | 6,128 | 100% | 6,428 | 100% |

Proportion of Transaction Amounts with Key / Non-key Suppliers Over the Years

| 2022 | 2023 | 20234 | ||||

|---|---|---|---|---|---|---|

| Contractors | Material and Equipment Suppliers | Contractors | Material and Equipment Suppliers | Contractors | Material and Equipment Suppliers | |

| Key Suppliers | 86.09% | 78.57% | 72.52% | 57.59% | 79.20% | 79.19% |

| Non-Key Suppliers | 13.91% | 21.43% | 27.48% | 42.41% | 20.80% | 20.81% |

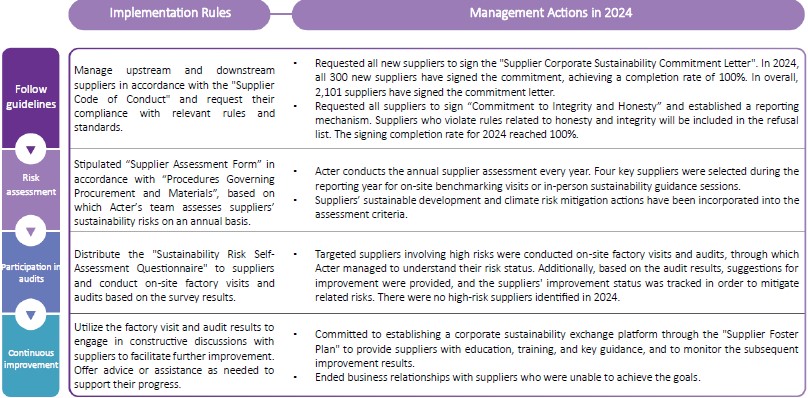

Supply Chain Management Implementation Policy

Acter has established a comprehensive sustainable supply chain management framework based on four core implementation principles—compliance with relevant guidelines, risk identification and assessment, participation in supplier audits, and continuous improvement. A “Supplier Code of Conduct” has been developed to ensure alignment between procurement practices and ethical expectations, thereby mitigating potential conflicts with ESG-related standards. Annual supplier evaluations and corrective action plans are conducted, with targeted support provided to suppliers for developing and implementing improvement measures. These efforts aim to reduce operational disruption risks and continuously enhance supplier sustainability performance.

Supplier Code of Conduct

Acter has established a Supplier Code of Conduct in alignment with international standards, requiring all suppliers to comply with the outlined principles. Suppliers are mandated to sign a Sustainability Commitment Letter as a prerequisite for qualification. Throughout the partnership, qualified suppliers are subject to periodic risk assessments and on-site audits to ensure ongoing improvement in sustainability performance. Beyond existing suppliers, Acter actively promotes and encourages suppliers to adopt the same ESG standards across their upstream and downstream partners. By leveraging the influence within the value chain, we aim to drive greater collective impact and foster shared value through mutual reinforcement of sustainability practices

New suppliers sign the implementation results

| 2023(No. of suppliers) | 2024(No. of suppliers) | |

|---|---|---|

| new supplier | 260 | 300 |

| Commitment to Integrity and Honesty | 100% | 100% |

| Corporate Sustainability Commitment for Suppliers | 100% | 100% |

Highlights of Supplier Code of Conduct

01

Labor

- No discrimination

- Fair treatment

- No child labor

- Working hours

- Salary and allowance

- Freedom of association and collective bargaining

- Free choice of employment

02

Health and Safety Standards

- Occupational safety

- Emergency response and preparation

- Occupational injury and diseases

- Industrial hygiene

- Labor work

- Machine protection

- Sanitation, food and accommodation

- Health and safety communication

03

Code of Ethics

- Business integrity

- No unjust proceed

- Information disclosure

- Intellectual property

- Fair trade, advertising and competition

- Protect identity and eliminate retaliation

- No conflict mineral

- No Privacy

04

Environment

- Environmental permit and compliance

- Pollution prevention and treatment; resource saving

- Hazardous substances

- Wastewater and solid wastes

- Emission of air pollutant

05

Management System Standards

- Corporate commitments

- Management responsibility and duty

- legal and standard essentials

- Risk assessment and management

- Improvement targets

- Training

- Communication

- Labors’ feedback and participation

- Audit and evaluation

- Correction procedures

- Documents and records

- Suppliers’ responsibilities

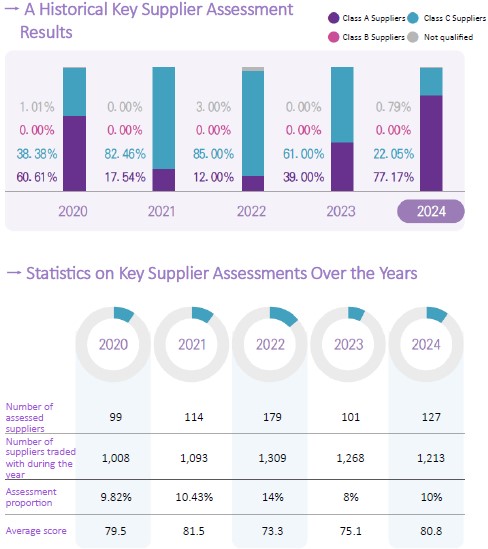

Supplier Assessment

Acter regularly conducts comprehensive evaluations of its suppliers based on criteria such as material and construction quality, delivery performance and construction achievement rate, pricing competitiveness, technical expertise, level of cooperation, financial status, and corporate sustainability performance. These assessments are carried out through both documentary reviews and on-site audits to ensure the effective implementation of sustainable practices across the supply chain. Suppliers achieving an overall score of 80 or above (Class A) are granted priority in contract awards when bidding prices are equivalent. Conversely, suppliers failing to meet the required standards may face a reduction in business volume or termination of cooperation. Suppliers scoring below 60 points are disqualified from engagement. In 2024, Acter completed sustainability assessments for a total of 127 key suppliers.

Supplier Sustainability Risk Assessment

To manage suppliers' sustainability risks, Acter identifies potential economic, environmental, and social risks through regular assessments. For suppliers identified as high-risk during this process, Acter conducts audits and provides guidance to effectively control and mitigate these risks. Acter also offers suggestions and tracks their progress in addressing deficiencies to strengthen the resilience of Acter’s supply chain.

| Facets | Content of Investigation | Supply Chain Action Plan |

|---|---|---|

| Economy |

|

|

| Environment |

|

|

| Society |

|

|

To ensure transparency in supplier assessment results, Acer randomly selects four key suppliers for on-site audits to assess their current status across various facets and to exchange ideas on their management methods and continuous improvement efforts. Acter also completes the "Supplier Visit Assessment Form" to document inspection highlights. Based on the audit results, the four suppliers selected for the year showed no deficiencies and did not require further observations.

Supplier Foster Plan

Acter engages in a supplier fostering plan with a focus on the four key aspects of “strengthening suppliers' response capabilities”, “implementing occupational safety and health management”, “improving quality management”, and “raising awareness of sustainable development”. Through this initiative, we have not only established a corporate sustainability exchange platform but also implemented supplier education, training, key guidance, secondary audits, and other approaches to enhance suppliers' progress on ESG factors and accelerate the sustainability of supply chain management.

Implementation Strategy/ Specific Approach of the Supplier Foster Plan

Assist suppliers in enhancing

their response capabilities

- Assist in offering resources and prevent supply chain equipment from being affected by the environment, as it can cause supply breakdown. This can help enhance suppliers’ response capability.

- Provide education and training programs to enhance suppliers’ expertise, which can be used to confront challenges in the industry or new technology.

- Enhance suppliers’ response capability through experience sharing.

Implement occupational

safety and health measures

-

- Provide training and programs to build suppliers’ awareness of environmental safety inspection.

-

- Implement occupational safety inspection.

Improve quality

- Provide training/ programs or share Acter’s experience to enhance suppliers’ expertise.

- Implement quality checks.

Enhance suppliers’ awareness

of corporate sustainability

-

- Establish a business sustainability exchange platform to share Acter’s experience and information on ESG, and request suppliers to comply with relevant policies to expand the benefits of corporate sustainability.

-

- Invite suppliers to participate in Acter’s ESG activities and plans.